Maximum web Width

1300mm

Printing cylinder repeat range

400 to 1100 mm

Web tension range

60 to 400 N

By perfectly integration of advanced electronics and ergonomically designed mechanical components to deliver optimum performance, better operational ease, faster print register response, higher productivity, better print quality, less waste, optimising ink solvent and energy consumption, faster job changeover etc.

Distinctively designed and precisely machined, strong steel frame structure machined using high precision CNC - VMC, maintains accuracy over long dependable life and ensures high print quality with optimum operating speed.

Maximum web Width

1300 mm

Maximum web speed

400 to 500 mpm

When the printing press operates at high speeds, it surpasses the capability of the human eye to assess the printed image’s quality. Therefore, a printing quality inspection system becomes imperative to scrutinize static images. The web inspection system for printing employs innovative technologies and methodologies to transform rapidly moving images into “still” images that are perceptible to the human eye. These images can be magnified partially to detect minor print defects promptly, thereby enhancing the quality of printed products. Furthermore, it allows for the separate observation of images in real-time, facilitating comprehensive quality assessment.

Maximum web Width

1300mm

Maximum web speed

200 mpm

This Solvent Base Lamination Machine runs up to 200 meters/minutes and it is suitable for PET/MET PET, BOPP/MET BOPP, LDPE, LLDPE and Laminates. Our machine is designed and developed according to industry standards for various solvent-base application like plastic films.

With the using of latest technology and well designed for easy interface, this machine is meant for maximum productivity and performance.

Maximum web Width

1300mm

Maximum web speed

350 mpm

These machines are equipped with latest technology for optimum performance and also has user friendly interfacing to operate. This solvent less machines are capable to handle various laminating jobs.

machines mainly for short and medium runs application for plastic films. This solvent less machine can used to laminate materials like Polyester, Paper, BOPP, Aluminum, Foil and LDPE.

Machine Speed

up to 450kg/hr

Maximum Film Width

200 mpm

Created to cover the growing needs of solvent-less lamination on flexible packaging market. Enhanced performance, on one hand, and the easy operating features on the other, are the main reasons to select this machine, joined with its ability to handle a wide range of laminating jobs. The machine has been specially designed, focusing on short and medium runs on solvent-less applications over plastic films. By perfectly integration of the new generation of electronics and ergonomically designed mechanical components, the machine is made to deliver optimum performance and productivity.

Maximum web Width

800 mm

Maximum Linear speed

160 mpm

The machine takes into account the production speeds, sealing consistency, quality, pulling speeds and sealing intensity to produce beautifully sealed and secured pouches even at higher speeds.

With the amazing servo controlled seal time and wait time functionality the operators can setup the machine in short time.

Maximum web Width

1300mm

Maximum Linear speed

1000-1200 mpm

The machine takes into account the production speeds, sealing consistency, quality, pulling speeds and sealing intensity to produce beautifully sealed and secured pouches even at higher speeds.

With the amazing servo controlled seal time and wait time functionality the operators can setup the machine in short time.

Maximum web Width

1300mm

Maximum Linear speed

1000-1200 mpm

The machine takes into account the production speeds, sealing consistency, quality, pulling speeds and sealing intensity to produce beautifully sealed and secured pouches even at higher speeds.

With the amazing servo controlled seal time and wait time functionality the operators can setup the machine in short time.

Maximum Linear speed

600 mpm

Minimum Slit Width

50mm and 25mm

With the combination of our proven Pelican SoloSlit and with the advantages of modern turret technology, ACROSTAR reducing down time, thus increases productivity compare to traditional duplex slitter (even at same operating speed).

Precise close loop tension control on rewinder using new generation of electronics offers maximum efficiency with wide range of substrates at high speed.

Maximum Linear speed

370 mpm

Maximum Web Width

1000 mm

Slitting and rewinding machine for paper , Poly , BOPP , Non Woven , Laminated Etc. A slitter machine (commonly referred to as a slitter rewinder) is a special type of equipment used to convert / slit many different materials so they can be cut down into narrower rolls.

Maximum web Width

1300mm

Maximum Linear speed

250 mpm

Maximum Roll Diameter

1000m

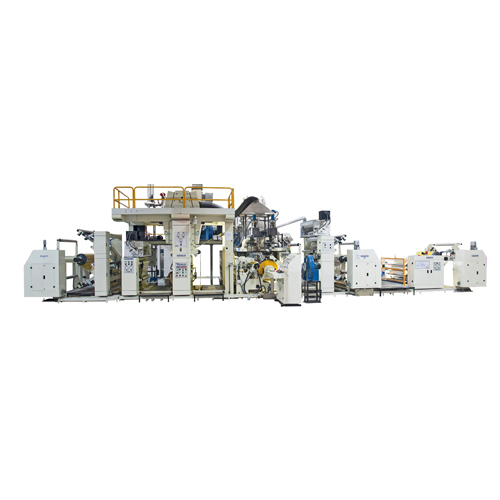

Extrusion Lamination necessity of Flexible Packaging. The demand of current and future of packaging Industry. Most of the products which are complex in structure and require good barrier properties converted by this process.

It is a complex but interesting process in the flexible packaging industry. There are many structure in day to day life which requires this process and people are also trying to convert lamination structure extrusion process.

Maximum coating width

1650 mm

Coating Thickness range

12 to 120 micron

maximum coating output

120 kg/hr

Over the years Cygnet Machinery has developed Extrusion coating Lamination Plant for Multi Purpose Applications to be processes on one single Equipment. Extrusion coating lamination is a process used in the packaging industry to create a composite material by combining different layers of materials like Woven Bags With Bopp & PP, Paper with Ldpe Coating, Non Woven with BOPP & PP, Paper With Foil Raffia with PP, Thus Extrusion Coating Lamination Machine manufactured by Cygnet Machinery can be used for Multi Purpose Industry like Flexible Packaging, Industrial Applications, Specialty Films, etc.

Maximum Output

300kg/hr

Maximum Film width

1200 mm

Windsor Machines successfully introduced the polyolefin dedicated blown film line in India. The path breaking POD series provides greater flexibility, increased productivity and superior quality in the manufacturing of Non Barrier Film applications. The POD lines consume less raw material leading to optimal use and conservation of resources.

LD Ratio

30:1

Maximum output

70 kg/hr

Film thickness range

20 to 100 micron

Cygnet machinery is one of the most preferred supplier for two-layer blown film machine, also known as a coextrusion or AB Layer blown film machine, it's a equipment used for the production of multilayer plastic films. It is designed to produce films with two distinct layers, each made of a different material or with different properties. Coextrusion blown film machines offer enhanced functionality and performance compared to monolayer machines by combining the advantages of different materials in a single film. The use of multiple layers allows for the creation of films with enhanced barrier properties. By selecting different materials for each layer, manufacturers can achieve specific barrier characteristics such as moisture resistance, gas barrier, light blockage, and aroma protection.

Maximum Output

300 bag/min

Bag Material

PP. LD, HM, BOPP

The Bag seam machine is a fully automatic machine with a folding device. The equipment is widely used in the processing of various printed or non-printed plastic sheets such as PE, OPP, BOPP,heat shrinkable films, etc. The plastic bags that use many side-sealing plastic bag making machines usually have stickers on them, which can be directly loaded into the product and sealed. Therefore, the equipment is widely used to make clothes packaging bags, bread bags, jewelry bags, stationery bags, cosmetic bags, and other products.

The side seal bag making machine delivers up to 300 strokes / minute and is suitable for LDPE / HDPE / PP / BOPP films. There are a various attachments available for this machine to make a variety of bags like handle punch, pre sealer, bottom gusset, inside / outside lip former , lateral sealer, perforation, tape applicator for courier bags, web aligner etc.

Maximum Width

1020

Maximum output

70 m/min

Washing Station

1 nos

This De-metalizing machine is widely applied to partly processing metalized film or laser hologram BOPP, PET, PVC film to open window partly by chemical washing-away methods for giving prominence to logo position, the see-through window is optional according to clients' requirements on size and shape.